How Gricd Mote is helping companies curb losses by providing real-time data on storage conditions

It’s a regular thing for businesses to record some losses at one point or the other. However, in cases where these losses are recurrent and tremendous each time, something needs to be done.

In a country like Nigeria, one of its key sectors, is the agricultural industry known to churns out tonnes of perishable farm produce daily. The problem is, if these perishable goods aren’t consumed within a given short timeframe, the losses are fatal. To ameliorate challenges, one innovative means would be the storage of perishable products. But industrial storage of perishables has its own challenges. Considering that storage of products that are perishable is a problem.

The team at Gricd came up with means to combat this challenge. Led by Oghenetega Iortim, Gricd found a way to curb the daunting challenges of storage and perishables through its product. Iortim runs us their direction and inspiration this week.

What exactly is Gricd?

Gricd is basically a startup that’s looking to solve the challenge of losses in the various sectors through innovation. We have a product called the Mote that provides real-time data on storage conditions of products either in storage or transit such that businesses or individuals could take proactive measures to curb those losses. Also, that data kind of help provides a basis for settlement, collection of insurance claims as well as mapping of infrastructure.

What’s the inspiration behind Gricd? Why did you start at all?

In 2015, I and a couple of friends decided to set up a farm in Benue state. The idea was to plant vegetables upon every circle and sell the harvest. We didn’t really take into consideration the kind of losses that would happen with delays coming from the off-takers and that became our reality. The fact that we were losing as much as 20-60% of the produce per circle. A year afterwards, we had to shut it down. I have an engineering background so I decided to try and solve the problem with the skills I have and that’s actually led to the development of Gricd.

We registered the company in 2017 but Gricd started out with a lot of research and development about existing solutions and how we could improve it. This happened by understanding the challenges of the existing Nigerian ecosystem especially in agriculture and healthcare and then building a solution that works effectively within this sector.

What’s the focus of both the product and the company?

Mote is a product, Gricd is the company. Gricd is a software company that provides data to enable businesses to curb losses. There’s Mote which we consider as the hardware, it is an enabler such that the hardware when installed helps businesses detect certain information such as location, temperature and humidity.

Temperature and humidity are factors that affect the chemical or the organic makeup of any agro and healthcare products. Monitoring the temperature and humidity are important to ensure that if it stays within the right parameters then the initial lifespan product will be extended. If it goes beyond those storage conditions, it means your product is going to be lost. Basically, the Mote is an enabler for the business.

What’s your fit in oil and gas?

There’s an aspect of the oil and gas which is environmental sciences. The environmental sciences deals with a lot of sample collection before bodies such as the department of petroleum resources issue out a certificate to fuelling stations or certain land fields. Before this, there’s always the process of sample collections. These samples that are being collected have chemical or organic compounds which if exposed to high temperature lose potency.

What Gricd is doing in the oil and gas is providing the Mote to businesses that are in the space of sample collection and transportation to laboratories to ensure that the potency of the samples being collected at these fields are maintained while also understanding where the asset is located per time.

Can you work us through your market? Who’s your ideal user and are you focused on B2B or B2C?

We’re mostly B2B and our ideal customers span across different sectors. Anybody who deals with temperature-controlled products either in healthcare or oil and gas samples being collected in the oil fields or in agriculture for people who stores vegetables.

We have a website application where they can visit and place an order and once users have the devices, they can set up via the software where they configure it to tie the hardware device to their software and use the product. We have over a hundred devices deployed for over three months. It’s a one-off cost for the hard but it’s subscription base for the software.

Are you mostly hardware-facing?

We’re a little bit of both — hardware and software — but mostly software-facing because we feel that the hardware is just an enabler which helps us gather the data but the software gives the analysis of the day which is key.

At the beginning of the startup when we were doing a lot of research and developing the technology that suits the environment, we were mostly hardware facing. But we’re software facing, I think as we grow and the IoT sector evolves, and more hardware companies that do similar solutions are produced, we’d typically focus on our software so that other hardware could be integrated into it.

How does your product affect the average person?

I think our product spans beyond the companies that we serve to the individuals who receive it. For example, healthcare; we have a lot of cases where individuals have died from impotent vaccines. In the agriculture sector, sub-Saharan Africa has about 220 malnourished children though we produce a lot, we also waste close to 70%. The reason for the wastage could be lack of infrastructure, knowledge and knowledge of infrastructure.

In certain locations, you don’t have access to cold rooms, generators or electricity to power the cold rooms as the case may be. For instance, people don’t know that their infrastructure is faulty or lacks power simply because of power failure especially in this part of the world. There’s also the lack of knowledge of infrastructure without knowing the exact location and the structure needed. Cold/code mapping is also critical, and this is one of the things that our solution provides to the market.

What are your challenges in this space?

I don’t see a lot of setbacks beyond the work we have to do which is marketing and awareness — informing people on the product. But at the moment we are a form of first-movers in the market based on the kind of technology we’re offering.

We have unhindered access to the market, it’s just about getting the right contract, making the presentations and closing the deals quickly. I wouldn’t say there are many challenges but I think if I want to speak of challenges, I’d say it’s sourcing our parts from outside the country and like every other business, the forex is a challenge. And the constant fluctuation of the currency tends to affect your prices as well.

To solve that, we’re looking at the possibilities of local content just that certain technological components can’t be found in Nigeria because they are not the manufacturers of some controllers we should have for our products so we need to always go to the foreign market. Import substitutions, once we achieve critical mass, we’d be breaking ours here in Nigeria such that it cuts down our cost significantly.

How about the industry, do you think it’s ripe enough?

Yes, I think the industry is ripe enough. From my experience and the meetings we have, I think it’s long overdue. These are national issues especially things like “Lasmal” and distribution.

For example, COVID-19 vaccines that are being produced now, the question has been how do we transfer them to the “Lasmal” and ensure that if anything arises while transporting it, we are aware. This is where we play, it’s not a question if it’s in the future or when it’s actually now, and the market is ready for it.

Beyond the oil and gas space, we’ve worked with sectors like the Nigerian Center for Diseases Control (NCDC) that makes use of the device to track the COVID-19 samples to know where they were but also ensure that the potency was kept. This is because if you’re spending millions of dollars or euros on procurement of vaccines, it’s only right to monitor them not just for the safety of the vaccines but also make sure that the potency of the vaccines was maintained. If you maintain the potency, it means that you achieve the target which is to typically reduce the pressure on the government in terms of expenditure in the healthcare sector.

If we check the agricultural sector, we go could talking about the statistics of the losses and how data could basically help a lot of businesses curb the losses. Even if it’s 60% of the loss incurred, it’s better than 220 malnourished people. The market is ripe, the solution is ripe and it’s time to actually get

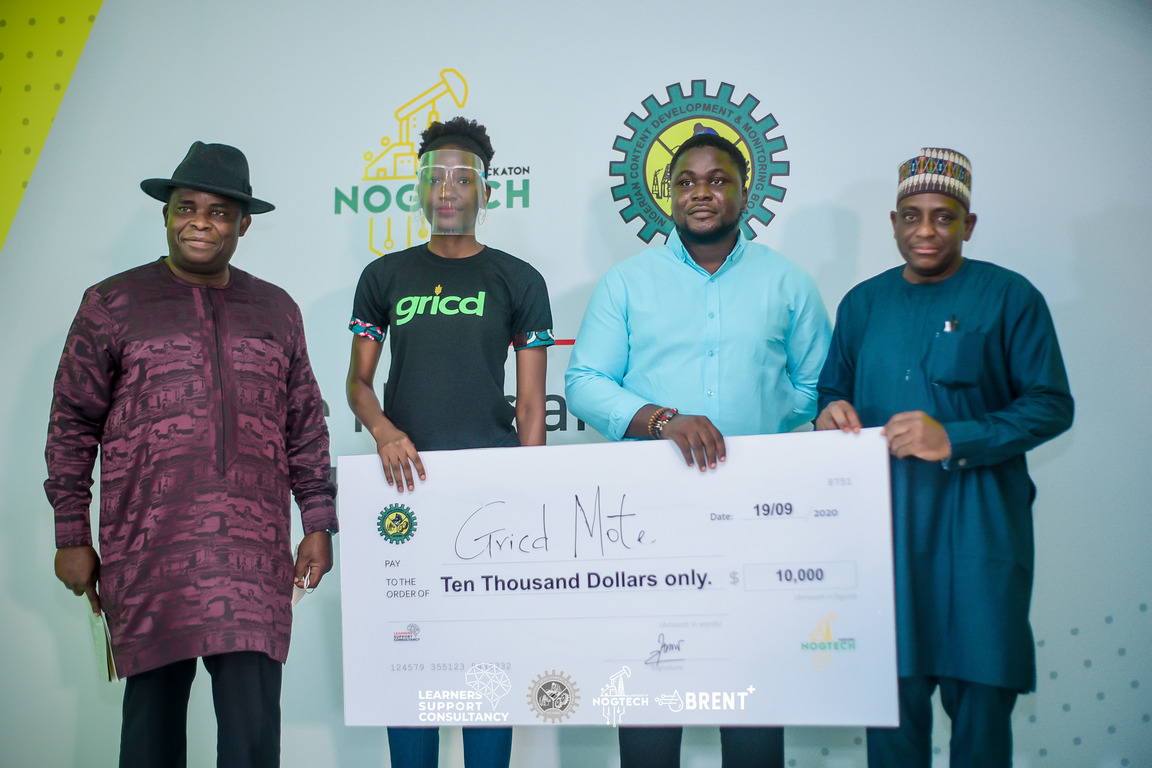

Have you been bootstrapping or gotten any funding before NOGTECH?

We’ve had previous funding before NOGTECH which includes funding from Cchub but it’s been a combination of investors funds and bootstrapping from mostly family and friends.

Walk us through your team. How do you operate?

I’m the founder and we have seven other people in the team ranging across experiences in the supply chain, product development, hardware engineering, software development as well as support. Combined we have experience of 40 years put together with people who have experience from the likes of Imperial Logistics, DHL, GE guard to mention the kind of experience we have on board.

How has the incubation helped you so far?

The incubation has been relevant to understand the oil and gas space much better. We’ve gone through various courses with individuals from the oil and gas space to everyday business activities we need to understand. But specifically in the oil and gas space, we’ve gotten to understand certain opportunities we could take advantage of as a local company. We’ve also understood that other aspects of the oil and gas space beyond the environment is where the product will be required. That has been of value to us for being part of the incubation programme.